WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Project Cost Of Setting Up A Cement Plant Pdf. India new projects, Mumbai ... Cement Manufacturing Plant Project Report: Cement Manufacturing ... setting up a rotary ...

Capacity Enhancement and Energy Conservation in Cement Plant V.K. Batra*, P.N. Chhangani**, Dinesh Satija*** and R. B. Garg**** Holtec Consulting Private Limited, .

McMaster-Carr is the complete source for everything in your plant. 98% of the products ordered ship from stock and deliver same or next day.

Dry, semi-dry, semi-wet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

It gets worse. The stickers—which run as high as $120 for a pack of 24—promise to assuage various ailments, including anxiety and pain, using something called ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

Gunpowder, also known as black powder to distinguish it from modern smokeless gunpowder, is the earliest known chemical explosive. It consists of a mixture of sulfur, ...

International journal of advanced scientific and technical research Issue 4 volume 1, January-February 2014 Available online on ...

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

The Beginnings of Portland Cement. Portland cement is one of many materials that can be made by making a finely-ground mixture of limestone and clay, and burning the ...

For information on opportunities to reduce sulfur hexafluoride (SF6) emissions from electric power systems, visit - https:// ...

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology Asia-Pacific, Brisbane, Australia e-mail: alex.jankovic@

The Monarch Portland Cement Company was founded in 1908 and reorganized in 1913 as The Monarch Cement Company.

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

The potential opportunities for improving energy efficiency and lower CO 2 emissions in raw material generation and production of concrete are smaller than in cement ...

Cement history, in brief, from the Greeks and Romans to the development of Portland cement

Large-Scale Production of Edge-Selectively Functionalized Graphene Nanoplatelets via Ball Milling and Their Use as Metal-Free Electrocatalysts for Oxygen .

Privately Produced Diesel Motorcycles by engine. Please note: All Motorcycle in this section have at least one major part, example Chassis or engine ...

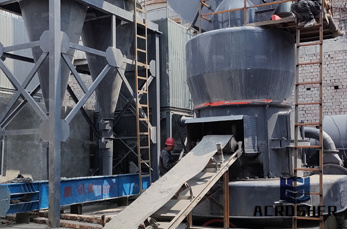

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Committed employees. Thanks to more than 100 years of experience in the production of cement, we know that success is based on people.

Convert Waste to Energy with Methane Production Learn how to convert manure and garbage to energy using this small-scale methane producing plant.

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

WhatsApp)

WhatsApp)