WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

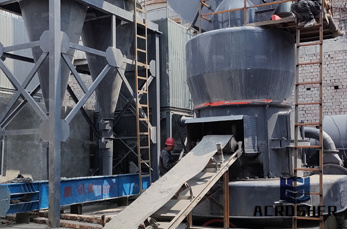

Girth Gear Lubrication System For Cement Ball MillRotary Advantageds of Girth gear lubrication system for Cement Ball Mill rotary kiln newtype unilateral singledrive doublesliding shoe bearing ball mill designed by our company adopts newtype shoemounted structure with such advantages as excellent lubrication effect light weight easy replacement and convenient maintenance

offers 156 bull ring gear products About 30 of these are ring gears 5 are spur gears A wide variety of bull ring gear options are available to you such as steel stainless steel

cement ball mill girth gear manufacturer gujarat crushing Iron Ore Sag Mill Troubleshoot In Cement Mill Gear Box How Much Crusher A cement mill had its Girth gear which is a huge gear surrounding the mill body and high vibration up to 14 mms rms align rotary ball mill rock crusher and mine solution Read more

Dec 12 2018· Crusher operation raw mill operation rotary kiln operation cement mill operation vertical cement mill clinker quality cement quality white clinker 14 opens switch on pressure relay 101 and solenoid valve 12 b Manual operation The following preparations are required for removing the gear below the mill a Pump oil out of

BIJUR DELIMON Lubrication Solutions for Ball Mills • Custom designed for optimal lubrication of Girth Gears and Pinions on rotating equipment • For harduous applications that require constant metered and direct lubrication with grease or high viscosity oils providing increased Mill output

The AirMax is a simple economical lubricator ideally suitable for airoil systems The AirMax is supplied with a 3 liter reservoir pressure gauge and oil inlet filter with the options of a oil pressure switch low level switch

Appliion of electric drives in cement mill In the cement industry SIMOTICS HV Series Hcompact is suitable for various kiln mill and fan appliions such as primary crushers raw mill drives raw mill ventilation kiln drives exhaust fans cement mill drives and cement mill fans More Details Cement Mill Girth Gear Pressure Switch

Tailings Loss In Chrome Orebeneficiation Plants

The switching device SGA is used as differential pressure switch in dualline centralized lubrication system When the differtial pressure is 50 bar andor 100

The switching device SGA is used as differential pressure switch in dualline centralized lubrication system It is mainly used in wind mill applications to suck off the waste lubricant rotary kilns winches etc It was developed to lubricate open gears or gear rims WSE Chain lubrication unit The central lubrication system WS

The ball mill's low pressure oil system pumps oil from the reservoir through a filter assembly to clean the oil before the flow is sent to the trunnion bearings During startup the oil is also pumped to the high pressure pump Dual cartridge filters connected in parallel continually clean the oil

Gearbo For Ball Mill Controlling Gearbo Contamination Ball Mill Drives We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly or individual mill drive gearboxes girth gears pinions and couplings as required

Dec 13 2018· Crusher operation raw mill operation rotary kiln operation cement mill operation vertical cement mill clinker quality cement quality white clinker Clinker and Cement 2232 Install a high temperature switchsensor interlocked to shut off the supply of fuel to a fired preheater also called girth gear or bull gear Main kiln gear

PRESSURE SWITCH 10 1 12 1 No NAME OF PARTS QTY WITH 1 CONTACT NAME OF PARTS TEMPERATURE 54 SWITCH No 1 QTY RESISTANCE BULB 1 RESISTANCE BULB 2 1 2 6300kW Planetary Gear Reducer for Cement Mill 3700kW Symmetry Type Gear Reducer for Cement Mill Inching Device for Cement Mill

Cement mill girth gear delimon pressure material temperature control in cement mill wikipedia the free encyclopedia a cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball

Advantageds of Girth gear lubrication system for Cement Ball Mill rotary kiln newtype unilateral singledrive doublesliding shoe bearing ball mill designed by our company adopts newtype shoemounted structure with such advantages as excellent lubrication effect light weight easy replacement and convenient maintenance

cement gear crushing commacongres Gear Box Lime Stone Crusher For Cement Industry czeueu Gear Box Lime Stone Crusher For Cement Industry Cement Plant Crushers Suppliers ThomasNet Manufacturer of standard custom compact twin shaft crushers for cement plant flux coal coke limestone gear reduction or motor cement plant crushers the pieces of gear crusher contre

Jun 25 2016· Change HSS bearings of Combfilex Gear Box Cement Mill 3 MBCC ASEC Flender SIEMENS 2015 Eng Moaaz Emad Gaber 15032015 2 Dismount Oil pipe and pressure switch in the front of the GB Fig 5 3 Dismount half bolts of the 2 flange cover one in the motor side and the other in the mill side Only half bolts which tight in the casing

cement mill gearbox horsepower cement mill gearbox output drive end bearing parallelvzwbe Tube Mills KHD International This is primarily due to the support bearing design and the mill drive whose planetary gear is mounted to the mill and built more than 1000 tube mills Online Chat Selecting Inching Drives for Mill and Kiln Applications the required mill speed in

WhatsApp)

WhatsApp)