WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

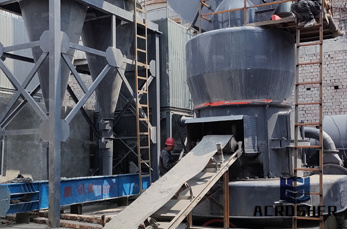

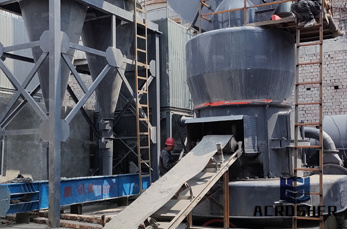

Operation and Elements of a Closed Circuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamber

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement

Feb 10 2016· Overall ball miil is good option for Cement mill but only has limitations for higher capacity as two ball mill to be installed for One VRM but in case of breakdown one ball mill can be in operation Trust this clear your clarifications on equipment selection for cment production Regards

Cement ball mill in the process of production and processing has high grinding efficiency large output and compared with the general ball mill this ball mill can save more energy consumption Our company can design and manufacture a special cement ball mill to meet the actual needs of users according to the output and fineness requirements of users

CHAENG cement ball mill equipment can reduce energy consumption by 30 and increase the processing amount by 1520 after transformation The cement ball mill can perform dry process production and also wet process production moreover it can do grinding and drying at the same time

Quality Vertical Cement Mill Cement Ball Mill Manufacturer Anyang Best Complete Machinery Engineering Co Ltd is best Vertical Cement Mill Cement Ball Mill and Roller Press Cement Mill supplier we has good quality products service from China 3298008487 863725081703

Cement Grinding Mill Cement Mill Cement Ball Mill manufacturer supplier in China offering Ball Mill Machinery Cement Clinker Grinding Plant Lead Tin Ore Flotation Processing Tank Industrial Conveyor Mesh Belt Drying Equipment for Drying Coal and Charcoal Briquette and so on

Ball mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill the closedcircuit ball mill has high efficiency high output low cement temperature and good comprehensive benefit

Chinas cement industry has been forced to eliminate the ball mill below 3 meters so all enterprises in the grinding ball assembly mill are using electric hoist lifting and unloading the drop is

China 279m Cement Ball Mill for Sale Find details about China Cement Ball Mill Cement Mill from 279m Cement Ball Mill for Sale Henan Hongke Heavy Machinery Co Ltd

There are 13544 china cement ball mill suppliers mainly located in Asia The top supplying country or region is China which supply 100 of china cement ball mill respectively China cement ball mill products are most popular in Africa Domestic Market and Southeast Asia

The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power and other industries to grind all kinds of ores

Find Cement Ball Mill manufacturers from China Import quality Cement Ball Mill supplied by experienced manufacturers at Global Sources We use cookies

Cement mill has features of high adaptability to raw materials continuous production and big grinding rate Cement ball mill can produce powder from various nonflammable and nonexplosive mineral materials with Mohs hardness below 93 and humidity below 6 such as barite limestone kaolnite ceram and slags etc

The cement ball mill is mainly used to grind cement clinker in cement production process and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill the quality of our product takes a leading place

The China cement mills vary from traditional ball mill to new European trapezium grinding mill In cement making plant cement grinding mill and cement crusher play a very important role They can crush or grind the cement to required fineness for industry application

Application of cement ball mill Balll mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials process

Dry Ball Mill Cement Ball Mill Ceramic Ball Mill manufacturer supplier in China offering Gold Mining Machine Dry Cement Ball Mill Gold Mining Wash Plant Sand Washing Machine for Sand Long Service Life Sand Ore Iron Powder Linear Vibrating Screen and so on

Nov 01 2017· Cement Mill Grinding Media Dear Experts I want to know about the GM size wise percentage distribution in a 2 chamber close circuit OPC ball mill Mill dim 34 x 125 Media load 128 MT high chrome Also let me know how do the supplier selected 80mm as max Ball size in this mill Please share the formula as well

A Ball Mill grinds material by rotating a cylinder with steel grinding balls causing the balls to fall back into the cylinder and onto the material to be ground The rotation is usually between 4 to 20 revolutions per minute depending upon the diameter of the mill The larger the diameter the slower the rotation

WhatsApp)

WhatsApp)