WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Raw Meal Grinding Vertical Mill Fundamentals Raw Meal Grinding Vertical Mill Fundamentals - ATOX Vertical Raw Mill grinds all types of raw materials The ATOX Raw Mill is a highly efficient mill that grinds all types of raw ...

vertical roller mill raw meal Sustainable cement productionpresent and future At the same time, the cement industry is facing challenges such as cost increases in energy supply, requirements to reduce CO 2 emissions, and the ...

Bag filter for kiln-/raw mill - Intensiv-Filter Nov 21, 2013 ... gearbox of atox raw mill. vertical mill made by fuller – Mining ... For Sale from Nelson Machinery. . fls fuller vertical roller mill inspection and... LM Vertical Grinding Mill ...

Key benefits Energy-efficient The mill uses five to ten percent less energy than other vertical roller mills and 30-50% less energy than ball mill systems High run factor Operating time availability is typically 90 to 95 percent Easy to ...

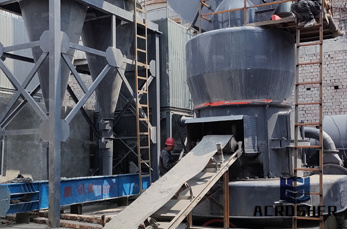

Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz ...

Vertical roller mill is mainly used for grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay ...

Coal Vertical Roller Mill (VRM) is an air swept, medium-speed, vertical pulverizer with integral classifier. It pulverizes coal by applying hydraulically-loaded grinding pressure through three grinding roller onto a rotating bed of coal.

Cement mill - Wikipedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills .

vertical roller mill raw meal Dalmia Cement - One of the Best Cement Companies in India Dalmia is one of the leading cement suppliers in India; it even supplies to the top companies. The Dalmia cement factory employs the best ...

How we make Cement – Sharrcem Dec 18, 2013 Vertical mills pulverize the raw materials through the pressure exerted by three conical 5th Stage – Raw meal Homogenization and Storage:. » Learn More Brochure EN PDF 4,3 ...

The QUADROPOL® roller mill. The new mill generation, tailored to market requirements. The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power combined with small ...

4 Quality and reliability right from the start are the glob-ally recognised benefits to be derived from Loesche grinding plants. As early as 1928, when the first Loesche mill came onto the market, the grinding principle of the vertical roller ...

3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement grinding. Today, however, the OK mill has become an excellent ...

High-efficiency mill grinding all types of raw materials ATOX® Coal Mill An extremely compact, air-swept vertical roller mill ATOX® Mill Retrofits Retrofit your ATOX mill and save maintenance time and money ...

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA ... PROCESS CONTROL INTERNATIONAL CEMENT ...

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and ...

Vertical roller mills are widely used in the concrete and mining fields, and are also used to process coal,lime and gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve ...

Vertical Roller Mill Overview Vertical roller mill is used in cement raw meal grinding processing, cement clinker, slag and coal cinder, with characteristics of simple structure, low cost of manufacture and use. Vertical roller mill includes ...

vertical raw meal mill technology book pdf, Gebr. Pfeiffer to supply the world's largest vertical roller mill for cement Pfeiffer to supply the world's largest vertical roller mill for cement . for this grinding project, Cemengal ordered an MVR ...

- 1 - Item Vertical roller mill for raw materials Application p rocess Raw material process Background Grinding raw materials needs lots of energy. Tube mills had been used for grinding, but the energy efficiency level was lower.

manuals for loesche cement vertical mill – Mining equipment . Know more about the vertical roller mill – shanghai Heavy Industry . has become the preferred equipment for milling cement raw meal in the modern cement .

Sinoma Technology & Equipment Group CO.,LTD On May 26, organized by China building materials federation, Sinoma-tec's "TRMR60.4 Raw vertical roller mill development and appliion of assessments"... Vertical Roller Mill - Heavy ...

The cement industry uses MPS mills for grinding cement raw meal, coal, cement additives as well as cement clinker. Vertical roller mills for grinding cement raw meal and coal are the standard today in numerous cement plants.

Overview Vertical roller mill has many different forms, but it works basically the same. All of these forms of machine come with a roller (or the equivalent of roller grinding parts), and roller along the track of the disc at the level of circular ...

WhatsApp)

WhatsApp)