WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Cement Grinding Mill Ball Size Sorting Equipment HOME Cement Grinding Mill Ball Size Sorting Equipment Stationary Crushers Grinding Mill Mobile Crushers Mining Machine European Type Jaw Crusher European Type Jaw Crusher is a new crushing machine the jaw

Sorting machine with two sorting cylinders Ideal for ball diameters from 50 100 mm Sorting machine with five sorting cylinders Ideal for ball diameters up to 50 mm Sorting capacity up to 12 th depending on ball size Adjustable vibration feeder and cylinders for optimum sorting performance Adjustable inputoutput gap between the cylinders

Cement ball mill is not only suitable for overflow grinding but also applicable for cyclic closeflow grinding together with powder collector There are two ways of grinding the dry way and the wet way Features 1 Can work with grinding and drying equipment simultaneously 2 Easy to adjust the fineness of grinding products 3

232 Media size The efficiency of grinding depends on the surface area of the grinding medium Grinding in a ball mill is effected by contacts between ball and ore particles The angle of nip is important and ball sizes must be carefully chosen in relation to the largest and hardest particles in the feed

The optimim capacity that will be compatible to ball mills is upto 50m diameter in shell The size will be upto the flange diameter of 60 m and height is about 30 m The max weight of single piece will be upto 50MT These specifications will go well with the rod mills and ball mills

Ball top size bond formula calculation of the top size grinding media balls or cylpebsModification of the Ball Charge This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency

16 in dia x 32 in long Can be reduced to 16 x 16 Can be used as a ball mill or a rod mill WetDry Grinding Continuous flow mill S ID 58655 Quote Denver 8 ft x 14 ft Ball Mills Size 8 ft x 14 ft Qty 2 Comes with Rubber Liners Falk Reducer Pinion Bull Gear Bull Gear Guard Bearings Location Mexico View m ID 592176 Quote

For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2g Blaine the cost of wear parts ball liners and mill internals is typically 015020 EUR per ton of cement For an OK mill grinding a similar product the cost of wear parts depends on the maintenance procedures ie whether hardfacing is

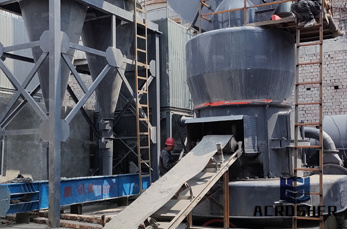

Vertical roller mill is widely used in metallurgy chemical industry and building materials especially in cement raw material crushing process in cement plant ball mill is also a very efficient grinding equipment so should you choose ve

cement grinding mill ball size sorting equipment Coal Grinding Properties Ball Mill CAVA of our mills we monitor every single detail With a grinding ball sorting machine from Injection into the 1st chamber via inlet Version Coal Version Cement Ceramic Tile We supply grinding media and ball mill liners to the ceramic tile

Cement Grinding Mill Ball Size Sorting Equipment Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dressing of both ferrous and nonferrous metals

The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dressing of both ferrous and nonfeCement grinding mill ball size sorting equipment

The Allmax II grinding ball 17 – 19 chromium content or more is especially suitable for use in the first grinding compartment in raw meal and cement mills Grinding Ball Sorting Machine Using grinding balls more efficiently Grinding balls such as Allmax grinding

Feb 10 2016· VRM has less flexibility in controlling particle size distribution Overall ball miil is good option for Cement mill but only has limitations for higher capacity as two ball mill to be installed for One VRM but in case of breakdown one ball mill can be in operation Trust this clear your clarifications on equipment selection for cment production

Grinding balls are sorted into appropriate size classes grinding balls that are not suitable for further use are rejected and then a set of grinding balls with appropriate parameters is used again The time needed to prepare the required set depends mainly on the sorting time

Cement Grinding Mill Ball Sie Sorting Equipment We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment

Overview of all of our mills Mills for grinding cement coal or minerals Christian Pfeiffer designs and builds grinding plants for many different feed materials and finished products Our mills are as varied as the requirements of our customers

Cement grinding mill ball size sorting machine Grinding balls sorter tab iteca automatic mill amp pellet press the grinding ball sorter allows the automatic separation of light and compact machine using retractable sorting rollers dusts steel scraps sort small balls from 12 to 40 mm dia

The ball size is often in the diameter range of 2075 mm The biggest size is chosen when the mill is used as a primary grinding mill For fine grinding of eg sands balls can be replaced by cylpebs which are heat treated steel cylinders with a diameter of 1240 mm and with the same length as the diameter

Ball mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill the closedcircuit ball mill has high efficiency high output low cement temperature and good comprehensive benefit It is the best choice for a cement plant

Ball mill is key equipment for grinding materials after crushing process It is used to grind kinds of materials into fine powder 2075micrometer Based on discharging type It

WhatsApp)

WhatsApp)