WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

This improved performance is made possible by the optimization of all ball mill system's parameters including the incorporation of a highperformance classifier improved control systems and grinding aids A closedloop ball millclassifier circuit can be positioned on load cells for weighing the total mill content of media and material

Our Carbide We use only the highest quality tungsten carbide in manufacturing our cutting tools The material itself is a micrograin carbide powder that has been blended with submicro carbide particles and cobalt powder that allows a very highdensity rod to be pressed

• Aluminium powder should be stored dry and any contact with water avoided One should ensure that the containers are always protected against rain snow and humidity Leaks in steam pipelines water pipes radiators or roofs should be repaired immediately

Specifically designed for machining aluminum stainless steel titanium and exotic alloy materials The high performance Elite Series for aluminum and nonferrous end mills have an engineered flute Shape designed for maximum rigidity maximum chip space and maximum consistency beyond traditional manufactured designs

Aluminum Nano Powder idea YouTube nano aluminum powder with a ball mill Boil Aluminum into gas form then solidify quickly trying to obtain should produce aluminum micro powder with no ball milling or oxygen ieFabrication of aluminum powder from foil scrap by a ation of aluminum

For superior performance in machining Exotics Aerospace Alloys Medium Alloy Steels Free Machining Steels or Aluminum NonFerrous Alloys be sure to visit our

An article tells me to ball mill my star composition prior to pressing my stars Maybe I just got some crystalline potassium nitrate that looks like sugar and I want to turn it into a fine talclike powder And perhaps most of all I want to be able to make commercialquality highperformance black powder

730 Corporate Woods PKWY Vernon Hills IL 60061 Phone 18007658665 18476343700 Fax 18476343755 18669418665 Technical Support 18888685988

Milldust is the term that is used for BP as it comes straight out of the ball mill before any granulation Second Step I take 16 ounces of the pine charcoal milldust add 16 ounces of water 10 to it and thoroughly incorporate the water into the powder with my gloved hands

Aqua V Mill 4 Flute End Mills High Performance Machining of a Range of Materials Variable helix variable index to reduce vibrations and chatter Versatile across a range of materials Available in Square End and Corner Radius Aqua Mill Nanolayer coating for high heat and wear resistance

The initial 7–15 μm Al was ball milled with a planetary ball mill Retsch model PM100 Germany in a 250ml stainless steel jar with 175 g of 95 mm stainlesssteel media A wet milling condition was used to achieve the desired particle size with 20 ml of hexane added to the 101 mass ratio of media to the Al powder mixture

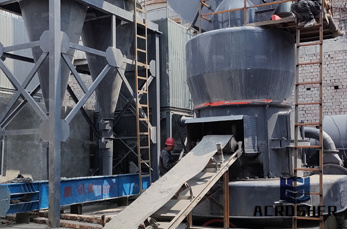

High Performance Aluminum Ingot Ball Mill For Aac Block Plant Find Complete Details about High Performance Aluminum Ingot Ball Mill For Aac Block PlantHigh Quality Aluminum Ingot Ball MillBall Mill For Aluminium PowderBall Mill For Sale from Supplier or ManufacturerZhengzhou General Mining Machinery Co Ltd

Ball End Mills have a hemispherical tip used to machine rounded details such as the metal bearing grooves found in machines Also called Ball Nose End Mills they are used extensively in manufacturing tools dies and machining complex three dimensional contours with a smooth finish Ball End Mills are very durable and come with an array of surface coatings tailored for milling a wide range

The AAMA 2605 high performance specification is the highest standard available for organic coatings on architectural aluminum extrusions and panels reserved for products that offer superior performance Coraflon fluoropolymer powder coatings combine the benefits of 1coat capability with high gloss

Henan Mingtai Aluminum Industry CoLtd has been engaged in aluminum processing for more than 20 years It has 6 semicontinuous casting production lines 10 continuous casting and rolling production lines 44 heavy coiler high performance foil rolling mill and other large processing equipment with an annual output of 770000 tons

Highenergy ball milling is a manufacturing technique used to reduce mix and alloy particles in the ceramic and powder processing industries originally created as a bulk powder process to create dispersion strengthened superalloys by the hot consolidation of ball milled powders Benjamin 1970

Dri Powder Ball Mill Dri Powder Ball Mill Suppliers Directory Find variety Dri Powder Ball Mill Suppliers Manufacturers Companies from around the World at ball mill sieve ball mill chocolate ball mill Mine Mill

When the advantages of both CIA and ball milling are combined to manufacture black powder the performance of the end product can reach or surpass commercial While the CIA method if properly executed ensures a superior integration of potassium nitrate the ball mill method is employed to intimately mix charcoal and sulphur

Ball nose end mills for roughing and finishing hightensile and hardened steels of up to 60 HRC SperoXR SperoXF Mills for highdynamic cutting with constant tool wrap HDC Highperformance milling in difficulttocut materials ZX Highperformance mills for integral aluminum components AXRV Universal high performance milling cutter with

offers 3445 aluminum ball mill products About 17 of these are mine mill 2 are grinding equipment and 1 are other fabrication services A wide variety of aluminum ball mill options are available to you such as ac motor dc motor and stepper motor

Gold Powder The gold bronze powder also named bronze powderpale gold powdercopper powderbrass powder gold bronze powder bronze copper powder g old copper powder bronze alloy powder It is a kind of buoyancy flake pigment is melted and ball milled by a certain percentage of cooper zinc and aluminum alloy and classified to the required specification

WhatsApp)

WhatsApp)