WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Make a Ball Mill in 5 Minutes This is for all the pyro nuts that I came across on Instructables This can be used to grind chemicals to a very fine grain or to polish says A ball mill is a type of grinder used to grind materials into extremely fine powder for use i

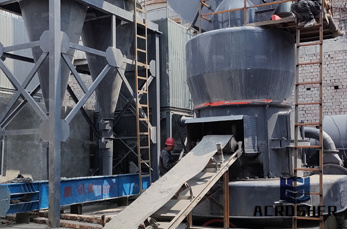

Ball mill is mainly used for grinding in mining metallic minerals and nonmetallic minerals cement refractories chemical power plant aluminum building material glass ceramic steel slag and fly ash follows more crushing and less grinding principle to save energy The feed size to ball mill shall be smaller than 25mm the output size can be adjusted by revising steel balls ratio

Ball Mill Operation Ball mills ride on steel tires or supported on both ends by trunnions Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive The prime movers are usually synchronized motors During rotation a portion of the charge is lifted along the inside perimeter

There is ball mill mineral that is commonly used in laboratories and are called planetary bill mill They are used to grind materials into smallest size while giving a demonstration to students or manufacturing something by professionals

How Ball Mills Work The following process description is based upon a ball mill used in the hard rock mining industry for liberating minerals from ore but the operating principle for ball mills used in other industries is the same Crushed ore is fed to the ball mill through the inlet a scoop small screw conveyor ensures the feed is constant

Mineral Processing equipment includes gravity sepa Fluorite Flotation Process Grid Type Ball Mill sale Overflow Type Ball Mill sale Rod Mill sale Energy Saving Ball Mill sale Cylinder Energy Saving Overflow Ball Mill sale Efficient Thickener sale Hydraulic Motor Driving Center Thickener

Ball Mill Rod Mill Grinding Ball Mill Rod Mill Grinding Grinding system is the section consuming power most in mineral processing plant It accounts for up to 40 of the total power consumption in mineral processing plant operations

The ball mill is a typical material grinder machine which widely used in the mineral processing plant ball mill performs well in different material conditions either wet type grinding or dry type and to grind the ores to a fine size Main ball mill components cylinder motor drive grinding medium shaft The cylinder cavity is partial filling with the material to be ground and the metal grinding balls

Ball mill grinder is usually used to grind crushed materials such as ores chemicals ceramic raw material and others This article mainly talks about ball mill for grinding calcium calcium carbonate powder is in greater demand worldwide in various industries

ball mill charge calculation per size rainbowridersin Calculate and Select Ball Mill Ball Size for Optimum In Grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Live Chat

The ball mill body or shell is of gray cast iron 12 inches inside diameter 7 inches between the two machined driving ribs Openings in the centers of heads allow free access of air during the grind duplicating commercial scale plant conditions The driving power is peripheral

In all ore dressing and milling Operations including flotation cyanidation gravity concentration and amalgamation the Working Principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals In the chemical and process industries grinding is an important step in preparing raw materials for subsequent treatment

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co Ltd is best Mining Ball Mill Ceramic Ball Mill and Cement Ball Mill supplier we has good quality products service from China

BG Series Roll ball mill a type of grinder machine is a cylindrical device used in grinding or mixing materials like oreschemicals ceramic raw materials and paints etc It is widely applied to industries of electronic material mineral material ceramics magnetic material building material biological medicine cement metal powder nonmetallic minerals etc

Brief Introduction of Ball Mill Ball Mill are giant drums that are filled to between 30 and 40 of their volume with freely moving grinding media in this case balls The diameter of the balls is between one and several centimetres to suit the application smaller balls for fine milling results and larger ones for coarser milling tasks

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size

With more than 100 years of experience in ball mill technology 's ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications both in open or closed circuits

【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders mainly used in the mineral processing industry both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size usually the manganese iron steel balls or ceramic are

The operating principle of the ball mill consists of following steps In a continuously operating ball mill feed material fed through the central hole one of the caps into the drum and moves therealong being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls

Ball Mills are generally used to grind material 14 inch and finer down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills they must be operated in a closed system with oversize material continuously being recirculated back into the mill to be reduced

With regards to ball mill with base plate except an additional base plate all the other parts are the same as those of ball mill without base plate Below 15 series is with base plate As per motor modes of ball mills they can be classified into YR motor and JR motor

WhatsApp)

WhatsApp)