WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement. Limestone is excavated from open cast mines ...

Cement Plant Equipments: We known for quality equipments manufactures and supplier of clinker grinding units, rotary kilns, crushers, conveyors for cement plants in ...

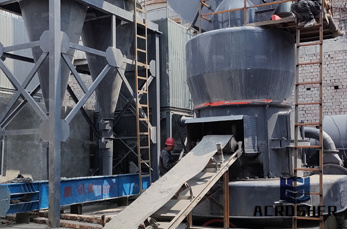

CHAENG | Great Wall Machinery provides you:Slag Grinding Plant,Cement Equipment,Vertical Mill,Ball Mill,Rotary Kiln For Quarry, Mining, Construction,Slag .

Cement grinding is a key process in the production. And the grinding process to complete the cement ground, is can the raw material of the cement grinding fineness of ...

Specialized Cement Mill. In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage.

CGM Cement mill, cement Grinding mill for cement Grinding process in cement plant. Ball mills and vertical mills are the best choice for your cement Grinding plant.

The various types of grinding systems currently being used for cement grinding in a cement plant are: • Conventional tube mill - Open and Close circuit

Do you want to show cement grinding mill process plant or other products of your own company? Display your Products FREE now!

ball mill,cement mill,grinding mill,crusher ball mill ball mill,cement mill,grinding mill,crusher ... During wet grinding process, when charge of ball-stone is up to 55% of net ...

Production process of cement ... In the closed circuit mill.4 Finish grinding process The finish grinding process is roughly ...

cement grinding processes [ 4.9 - 3986 Ratings ] The Gulin ... grinding process of cement – Grinding Mill China. Cement mill – Wikipedia, the free encyclopedia ...

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity.

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

The use of a good Cement clinker grinding aid can be vital in today's increasing material demands. Along with the obligation to process increasingly larger ...

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology Asia-Pacific, Brisbane, Australia e-mail: alex.jankovic@

Cement mill resizes rocks into cement powder which meet the requirements of cement grinding process. Cement grinding plant includes all kinds of powder mill.

Grinding trends in the cement industry - Cement Lime Gypsum. Each of the mill types and the associated grinding process are therefore more suitable for some ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY MEANS OF CLOSED MILL CIRCUIT MODELING A Dissertation by GLEB GENNADIEVICH MEJEOUMOV .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process .

Energy-efficient grinding mill designed for a variety of cement types

The company is capable of offering complete dry process cement production line construction service, including engineering design, ... for drying and grinding mill, due .

WhatsApp)

WhatsApp)