WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

High-energy ball milling uses mechanical action to introduce deformations into a material's crystalline lattice,

Planetary Ball Mills ... High-speed and versatile. ... Extremely high-speed milling down into the nano range ; Up to 1100 rpm ;

Design and Optimization of Ball Mill for Clinker ... It appears to take almost 60 hours ball milling to get 25 nm ... work,laboratory ball mill uses 3 ...

What Is The Use Of Ball Milling Technique. Ball mill - Wikipedia, ... most of the above research works uses actually a new ball- milling technique ...

Large-Scale Production of Edge-Selectively Functionalized Graphene Nanoplatelets via Ball Milling and Their Use as Metal-Free Electrocatalysts for Oxygen Reduction ...

Quick & Easy Black Powder Ball Mill By Ned Gorski. Take just 20 minutes to read this article, ... The ratios: This is the most important factor for ball milling success.

The effect of ball milling on the microstructure of powder metallurgy aluminium matrix composites reinforced with MoSi 2 intermetallic particles

How to Use a Ball Mill Safely and Effectively ... ball milling is the best way for the amateur fireworker to reduce particle size in ... whatever charcoal one uses.

Science and Technology of Advanced Materials 7 (2006) 839–846 One-dimensional nanomaterials synthesized using high-energy ball milling and annealing process

Manufacturing of aluminum flake powder from foil scrap by dry ball milling process Seong-Hyeon Hong*, Dong-Won Lee, Byoung-Kee Kim Department of Materials ...

The increase in the ball-milling time also caused a continuous decrease in the sample grain size until 48 h, ... 209-220 215 uses the explicit central difference time to ...

Choose from our wide variety of grinding media for crushing and grinding in a mill. We carry ceramic grinding media, milling balls for wet and dry grinding

most of the above research works uses actually a new ball-milling technique: ... Ball milling - IEEE Conferences ... For more what is ball milling technique ...

pretreatment uses lower temperatures and pressures, this process produces a large amount of salts during the ... Ball milling has a high energy requirement

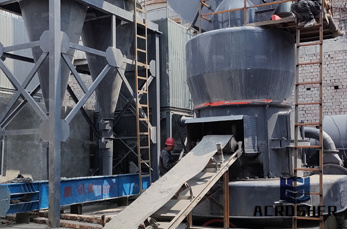

Ball Mill Grinder Machine – Grinding and Milling FAB 3R. A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Find here details of companies selling Ball Mills, for your purchase requirements. Get latest info on Ball Mills, suppliers, manufacturers, wholesalers, traders with ...

Scalable Exfoliation Process for Highly Soluble Boron Nitride Nanoplatelets by Hydroxide-Assisted Ball Milling

CNC Milling: Introduction to cutting tools . ... A ball nose end mill, also ... Non-center cutting mills are used only for side milling. When choosing a ball end mill ...

Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

2013-12-23 · Practical 1: Title: Ball Milling. Sieve. The sieving process in this experiment uses a stack of sieves which have the smallest mesh above a collector tray ...

Drug Development and Industrial Pharmacy ... Ball milling is frequently used to reduce the ... This website uses cookies to ensure you get the ...

Ball-milling in liquid media: Applications to the preparation of anodic materials for lithium-ion batteries

WhatsApp)

WhatsApp)