WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

To be worth while the tonnage must be counted in millions of tons Impurities in Iron Ores There are certain impurities that lower the value of iron ores or may even make them valueless Sulphur in the ore goes partly into the iron and steel and makes them brittle While it is

This list contains a list of all blocks and items Minecraft item id list and Minecraft block id list with all metadata variations for Minecraft 1122 Registry name and

Sand Making Powder Plant Iron Ore Design Sep 12 2016 sand making powder plant iron ore design sand making powder plant coal design solution for ore mining sand making crushing plant flow more vsi6s1263 vertical shaft impact crushersand making machine obedience to the idea to improve and develop equipment sand making rate extend spare part the rotor adopts the advanced 4

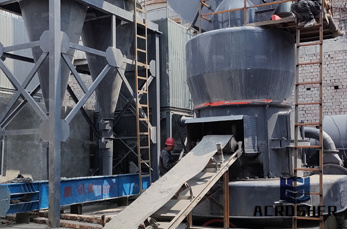

This picture is of an early iron ore sintering plant used to agglomerate powder prior to melting to make steel A modern iron ore sintering plant where production rates of sintered material reach upwards of 20000 tonnes per day A Gupta DS Yan in Mineral Processing Design and Operation 2006 Learn More

Crushing Plant Design and Layout Considerations crusher layoutA typical low speed roll sizer plant is shown in Iron Ore Co LabCityNF "Mineral Process Plant Design" Chapter 40 Society of Mining

Iron Ore Agglomeration Ø Sinter Process The sinter process was introduced around 1910 to treat flue dust extracted from blast furnace exhaust gases It was quickly adapted to agglomerate fine ore and its use spread rapidly At the sinter plant preblended fine ore is mixed with • coke breeze small particles of coke from the screening plant

2019522 · magnetic separation process iron ore beneficiation plant or iron ore processing plant is made up of jaw crusher ball mill spiral classifier magnetic separator concentrator and dryer etc since this magnetic separation process is advanced utilization rate of minerals can reach 90 water and power consumption is little

Julie DeLeon of Groundwork Design created an interesting play on the traditional flowerbed using Ores FŭSE Planter Trays that integrate into the suspended deck system Combined with planters of varying heights the impact is equally bold and serene

Manganese Iron Beneficiaiton Crusher Design Manganese Iron Beneficiaiton Crusher Design The other is magnetic separation production line which is widely used to process iron ore manganese ore etc Production Process of Ore Beneficiation Plant The raw materials will be firstly sent into crusher machine for primary and fine crushing and then the

The Ore Washing Plant has an internal tank of 10000 The Crushed Ore is put into the topright slot of the GUI above the recycling symbol It will be purified to make one Purified Crush Ore two rarely more Tiny Piles of Dust and one Stone Dust The type of Tiny Pile of Dust depends on the material

First import your ore texture Next create a block element and set up your textures Setup your block settings Configure your block generation properties Test your ore in the test environment Block Settings for Ore This section lists the settings Minecraft uses for there ore blocks you can also use your own settings or use the settings listed below

Jun 24 2015· 54 46 PLAN OF WORK 1 Since design and fabrication of iron ore sintering process involves proper understanding and to have desired strength and quality of sinterKeeping this in mind suitable process and materials are selected for the laboratory scale sintering machine 2

Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make steel is the only supplier in the world that has both the Straight Grate and the Grate Kiln process for pelletizing

Iron ore is the primary raw material from which metallic iron is extracted to make steel The rapid increase in crude steel production in the last decade has seen major expansions in world iron ore production from around 1 billion tonnes Bt in 2001 to over 29 Bt in 2012

Pure Iron Ore Type » Material Base » Common Stone Pure Iron Ore Lauan Windblade Windblade2 Common Stone Aluminum Ore Pure Iron Ore Mantasas Mantasas1 Common Stone Pure Iron Ore Cantaloupe Gum madylinm Pure Iron Ore Pure Iron Fillet Rivet EvilSanta EvilSanta1 Pure Iron Ore Pure Iron Claw Marble acct45 acct45 2

GCM has established a complete management system from initial consultation solution design onsite visit machine preparation and shipment to aftersales feedback to effectively ensure rapid and timely transmission of information so that the specialized services and technical supports can be provided by the correct persons at the correct time

Moreover our Iron Ore Beneficiation Plant are provided in various technical specifications and at affordable prices Besides from both the above ore beneficiation plants we are also providing Iron Ore Beneficiation Plants These are very helpful in separating iron mineral from impurities out of which former holds greater importance

Feb 22 2020· Iron ore sintering is a type of powder metallurgy used to pretreat iron before using it in manufacturing applications Sintering involves heating iron powder to partially but not completely melt the iron particles The exact process used and additional elements involved vary

Obtaining Iron Ore from Iron Nodes Edit Iron Ore can mainly be extracted from Iron Nodes that often come in patches of 24 Nodeblocks embedded in other rocks all over the Stalactite layer underground that spans the whole game world and is accessible through occasional large Caves

Iron ore is most often found in the forms of hematite and magnetite Learn what makes those types of iron ore different and make an informed investment

WhatsApp)

WhatsApp)