WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

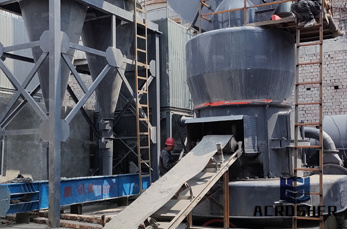

The Vibrating Feeder Vibratory feeder is used to transfer the large size materials and granular materials from Silo to receiving device uniformly periodically and continuously in the production flow and to feed materials into the crusher continuously and uniformly also

Phosphate rock vibrating screen legendhotelrice of screen vibrating machine for phosphate ore sa phosphate rock crusher machine for sale is a global supplier and vibrating screen rock phosphate crushing plant power consumption rock ive chat

The grizzly bars are often constructed of manganese steel but can also be made from ceramic materials Typically grizzly screens consist of a screening body is connected to a tray materials enter the vibrating screen through a feed box located at the base of the tray

Vibrating grizzly feeders for rock sand dirt and gravel engineered for your material handling needs at Rock Systems Available for sale rent or lease

Product Application Feeding machine Vibrating grizzly feeder is used for feeding the materials from the silo to receiving device evenly regularly and continuously Vibration feeder is widely combined used in crushing and screening equipment for metallurgy coal mineral processing building materials chemicals abrasives and other industries

Phosphate Rock Industrial Vibrating Feeder Kaolin Vibrating Feeder Dierenklinieksoestdijk Vibrating feeder vibrating feeder is a kind of lineardirection feeding learn more belt conveyor sam delivers the worlds most comprehensive range of heavy he vibrating feeder produced by our company is a linear vibratory feeder with the features of chat online

SW grizzly feeders are specially developed for mobile and portable plants and small to medium size stationary plants Compact and high capacity with an effective grizzly design and an optional second deck for fines removal they are suitable for a wide range of applications Request a quote Find an office

's range of grizzly feeders is known as VF Series grizzly feeders VF Series grizzly feeders are widely used in mines quarries gravel pits and by crushing and screening contractors with rock gravel slag or recycled industrial and other materials Configurable for a variety of needs offers an extensive range of grizzly designs with customizable configurations to fit your needs

The Vibrating Grizzly Feeder consists of a pan section at the feed end to receive and start segregating the material The discharge end consists of a grizzly section with openings that allow the undersized material to pass before discharging into the crusher

SV grizzly feeders are designed for high capacities from 170 to 2040 tons per hour in primary and secondary feeding applications They come in three main types and many sizes to balance demands for capacity impact resistance weight and installation dimensions

Buy used Grizzlyfeeders from AM King Industries We can help guide you to the best solution for your equipment needs UNUSED Type SV1562D Vibrating Grizzly Feeder 60 W x 20 L Manufacturer Inventory ID 11CSF02 View Details Type M4824 Grizzly Feeder

Feeder systems for rock sand dirt and gravel Contact Rock Systems for loading hoppers vibrating feeders truck unloaders dozer traps bins and more HeavyDuty Hoppers Vibratory Feeders Truck Unloaders Dozer Traps

Lippmann heavyduty vibrating grizzly feeders are ruggedly constructed for proven dependable and continuous operation These builttolast feeders do a superior job of metering the material to the crusher removing fines from the crushing circuit and absorbing impact

What passes through the grizzly bars lands in the hopper and falls onto the Vibrating Grizzly Feeder VGF The VGF located at the bottom of the hopper removes fine material like sand and small stone and provides a continuous rate of feed into the jaw crusher

Lippmann heavyduty vibrating grizzly feeders are ruggedly constructed for proven dependable and continuous operation These builttolast feeders do a superior job of metering the material to the crusher removing fines from the crushing circuit and absorbing impact from

Vibrating Screen – Fabtec "ProScreen" Portable Conveyor Screening Plant 1 – one – Fabtec Model 1 "ProScreen" Portable Conveyor Screening Plant with 12' wide receiving hopper with sloped grizzly section spaced at 6" for oversize protection variable speed 24" wide belt feeder 30"

Many customers add optional grizzly bars allowing it to size as it feeds When you purchase a SMICO aggregate feeder you guarantee that your company is buying one of most heavy duty feeders on the market today Whether you need a custom grizzly screen or a standard vibratory feeder

New and Used Industrial Vibrating Pan Feeders for Sale Savona Equipment is a vibrating grizzly feeder supplier worldwide for complete aggregate recycling mining and sawmill operations A vibratory feeder is an electromechanical instrument that uses vibration to transport feed material to a process or machine Vibratory feeders use vibration and gravity to move material

The vibrating grizzly is used to separate ROM feed material into fractions prior to the primary crushing stage of the process The pan deck is usually no more that 1 meter long whilst the grizzly bar section can be over 5 meters in length with varying widths from 900mm to 2400mm

Savona Equipment supplies grizzly feeders worldwide for large primary ore crushing at aggregate recycling mining and sawmill operations We manufacture hopper grizzlies that are ideal for removing undersized rock and ore from feed material before primary crushing equipment New used Grizzly hopper feeder parts are also stocked for sale

Grizzly Screens Feeders are used in primary crushing operation in Rock Phosphate Mining as scalping screen of the Primary Ore Crusher to separate undersized and oversized ore Typical separation is at 80 mm Grizzly Screens Feeders are also used as Feeders to reclaim ore from HoppersBins

A vibrating grizzly screen has been developed as a distinct improvement over the fixed grizzly now in such wide use It combines the functions of screening and feeding the ore to the primary crusher and by eliminating the undersize product in the ore feed to the crusher

WhatsApp)

WhatsApp)