WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

crushing, screening, washing, grinding equipment in ... CGM mining application. Mining and construction equipment manfuactured by CGM Machinery plays an ... Chapter 7 Grinding Mills,ScienceDirect 7.1. Introduction.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

Cement Mill operation.MP4 May 12, 2011 This milling operation used to further grinding Limestone. This is a ball type mill. feed rate is around 30 tons per hour. Get Price Cement Plant Operation Handbook | Mill (Grinding) - Scribd I ...

cement mill operation pdf - rock crusher and mine solution ... cement mill operation pdf - Grinding Mill China. cement ball mills theories and principles pdf. fls cement ball mill erection procedure download in pdf ... Read more

The construction and operation of cement plants carry the potential to have a profound impact on the local ... Grinding media sorting and balls | Magotteaux Grinding media. Grinding balls are only one type of grinding media ...

Optimizing the operation of the cement mill | Industrial Efficiency ... Ball mills account for the majority of all mills in cement plants and therefore the optimization of established ball mills implies high savings potentials. Parameters...

Application of ESP for gas cleaning in cement industry - ResearchGate by-pass, clinker cooler, cement and coal mill, in terms of exit gas quantity ... Cement mills - SKF Harsh, potentially costly operation. Exposure to elements ...

cement ball mill operation – Coal processing system Machine . Find the Right and the Top cement ball mill operation for your coal handling plant! , a mining machines manufacturer in china focus on your local solutions ...

Ball mills account for the majority of all mills in cement plants and therefore the optimization of established ball mills implies high savings potentials. Parameters that hold potential energy savings are load level, revolution speed ...

Optimization of Cement Grinding Operation in Ball Mills Contact Us » Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and ...

03 CEMENT MILLS Two-chamber ball mills for the cement industry are available in different designs. The bearings can be either trunnion bearings or slide shoe bearings. The drive can be confi gured as a girth gear and pinion, lateral ...

About Us - Damper Don Website North American Damper Companies. ... becoming AMF-Vulcan, Inc. The entire operation is now under one roof and ... damper and expansion joint solutions to the Power, Cement, Chemical, ...

VRM or ball mill for cement grinding? Mill operation and maintenance ... The moisture content on the kiln raw materials is also higher than the cement mill feed, which is generally dry. » Learn More Cement mill,cement mills,cement ...

Competence in cement - Gebr Pfeiffer SE mills are used for grinding cement raw material, cement, automatic operation of the MVR roller mill even with, pressure ... Electric Actuators for Cement and Lime Industry, Beck actuators ...

ball mill for cement grinding The STANEX diaphragm is suitable for all applications, even for mills operating with high material flow rates and moist mill feed. ... The cement mill - Understanding Cement Cement clinker is usually ...

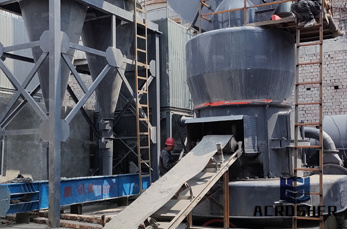

vertical cement mill in operation In 1935 Loesche supplied a first cement mill to. Brazil. Then lish the grinding of cement in vertical mills. It ensures low-vibration mill operation even in the. Learn More vartical cement mill process ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology F.L. 2 Introduction Around 110 years ago a Danish engineer, M. Davidsen, patented a ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of ...

CEMENT MILL OPTIMISATION – CASE STUDY V.K. Batra*, D. Bhaskara Rao** and Raju Goyal*** . Operation of the mill in auto mode as far as possible ... Cement mill can be in operation continually and easy to control grinding ...

Building Materials Equipment - Cement Mill, Raw Material Mill, As for different types of cement mills, we use proper driving method and the main .... Working Principle The raw coal goes into the feeding device of the grinding mill ....

Mining and cement industries news 2017 March 07, 14:00 SKF to highlight gearbox remanufacturing service at CONEXPO-CON/AGG 2017 2017 March 06, 14:00 SKF unveils new machinery health monitoring solutions at CONEXPO ...

Images foroperation of cement mill on standard modules. 2. The ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate... Scale and Cement Milling Operations ...

Ceramic Mill Relining and Refurbishing,Paul O. Abbe Ceramic mill linings will eventually wear down and need replacement. Even old pebble mills with Burrstone linings can be relined with high-alumina brick.

Do you want to show cement ball mill design operation or other products of your own company? Display your Products FREE now!

WhatsApp)

WhatsApp)