WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Proto3000 offers you a collection of dental milling machines with the option to perform wet and dry milling. Create powerful results with our highly precise dental equipment. ... 3D Engineering Services 3D Services 3D ...

Corn wet milling and dry milling are the predominant methods of processing corn and each method produces distinct co-products. Read more here. ... Approximately 20% of the annual corn harvest is currently used by industrial corn ...

Dry milling of grain is mainly utilized to manufacture feedstock into consumer and industrial based products. This process is widely associated with the development of new bio-based associated by-products. The milling process separates the ...

Dry Milling, Wholesale Various High Quality Dry Milling Products from Global Dry Milling Suppliers and Dry Milling Factory,Importer,Exporter at Alibaba. MENU MENU Alibaba Sourcing Solutions Help & Community ...

Ball Mill Loading - Wet Milling Ball Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct ...

Ball mill - Wikipedia, the free encyclopedia Different from wet milling and dry milling respectively, the balling mill can get the .... Low pressure electric control system, adopt PLC across-the-aboard monitor Temp, ... The ball mill is kind ...

Materials, such as ores, chemical substances, ceramic raw materials, magnetic coatings and paints, can be milled using a dry milling or wet milling process. In general, dry milling cannot break apart a product to save its parts for ...

Wet Milling, Wholesale Various High Quality Wet Milling Products from Global Wet Milling Suppliers and Wet Milling Factory,Importer,Exporter at Alibaba. MENU MENU Alibaba Sourcing Solutions Help & Community ...

Wet milling Wet milling with IKA's inline machines is a safe and efficient alternative to dry grinding. Dry grinding creates a lot of dust which causes the need for proper filtering systems. This can be of particular importance during ...

Wet Milling, Comminution and Emulsifying Equipment Glen Mills Inc. distributes and maintains stock of equipment from some of the world's best manufacturers of Wet Grinding and Milling equipment. Styles of mills we sell include ...

wet ball mill operation in gold milling Gold milling equipment supplier,Gold ball mill,Grinding . Gold Milling Process. Gold ore milling operation consists of crushing and grinding process. » Learn More different wet ball milling and dry ...

2015/03/30· Act Smart With Both Wet and Dry-Milling Options In today's restoration environment there's a growing need for both wet and dry milling systems and despite the increased popularity of glass ceramic, we don't foresee any In a ...

2000/10/15· Stainless steel can be gummy enough that coolant may be needed as a lubricant when a ball-nose or other round-profile tool is used. That was the case with this Stavax 420 stainless steel mold core. When dry milling ...

2015/11/09· Dry Milling or Wet Milling: What's the Best Direction to Take Your Dental Lab? Published on November 9, 2015 Chris Frye Follow Following Unfollow Chris Frye Sign in to follow this author Sales Manager at Whip Mix Corporation ...

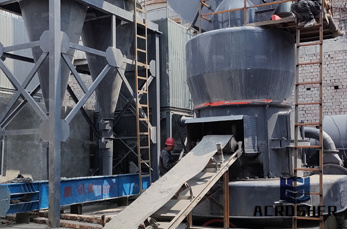

Successful Case Great many plants designed by MAC are built in countries and many of them has become the classical ones in local market. »Read More Good Solution MAC is quite experienced in construction, milling and mining ...

Wet-milling is a process in which feed material is steeped in water, with or without sulfur dioxide, to soften the seed kernel in order to help separate the kernel's various components. For example, wet-milling plants can separate a 56 ...

Wet Milling or Dry Milling? Learn the differences, materials best for each type of milling and how to determine your return on investment. Products Resource Library Shop Find a Dealer Dry Milling or Wet Milling: What's the Best ...

1980/01/01· Combined dry-wet milling process for refining corn US 4181748 A Abstract A continuous process for refining whole grain corn to obtain a prime corn starch fraction, an animal feed product and, optionally, corn oil. The process ...

Goals / Objectives 1. To determine the best conditioning parameters (misture, time, and teperature) to remove the pericap of selected Kansas sorghum hybrids using dry milling procedures. 2. To test dry milling laboratory procedures ...

Effect of Milling Environment on the Breakage Rates in Dry and Wet Grinding Abstract In ball milling the rates of breakage vary primarily with the size distribution of powder in the mill. Using an approximate solution to the batch ...

CORiTEC 240i The Dental Mill with Wet/Dry Milling Option The dry dental milling unit (wet milling optional), which is ideal for wet processing of glass ceramic blocks, feldspar, lithium disilicate. » Learn More wet milling and dry milling ...

2016/10/21· めまれている· Now chatting: Contact Us: Energy Efficiency Improvement and Cost Saving Opportunities for Corn wet milling is the most energy intensive ...

Wet milling is robust, relatively easy to implement and offers a range of benefits over dry milling for pharmaceutical, food & beverage, personal care and ... The Application Challenge During processing, many solid/liquid blends develop ...

Rice flour from nine varieties, subjected to dry- and wet-milling processes, was determined for its physical and chemical properties. The results revealed that milling method had an effect on properties of flour. Wet-milling process ...

WhatsApp)

WhatsApp)