WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process .

Cement manufacturing process - components of a cement plant from quarry to kiln to cement mill.

Though "cement" and "concrete" are often used interchangeably, concrete is actually the final product made from cement. The primary component of cement is ...

Slag is the glass-like by-product left over after a desired metal has been separated (i.e., smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

Lucky Cement Limited (LCL) is one of the largest producers and leading exporters of quality cement in Pakistan, with a production capacity of 7.75 million tons.

Nelson Machinery & Equipment Ltd. New & Used Mining & Mineral Process Equipment For Sale #equipmentProper #miningProper . Specializing in the sale of second .

How cement is made and history of Portland Cement

Brochures within the Schenck Process Group . The brochures below can be downloaded directly. Just click on your selection. You also can order our ...

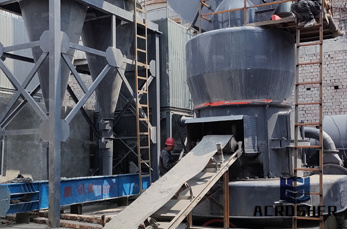

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology F.L.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

How Cement is made at Continental. Cement is made from common materials such as limestone, clay, silica, and iron ore. Principle raw materials are a blend of 88% ...

Heavy-duty performance 2 Ideal for both prehomogenisation and buffer storage of raw materials, FL stacker and reclaimer systems have an impressive track record ...

Coal washing plant with Density separation, flotation is used for coal beneficiation, cleaning process to sepatate rock, ash, dirt in India, Indonesia.

How is cement manufactured? Learn cement manufacturing process thoroughly.

sale buy used machinery, second hand machinery used steam boilers used chemical machinery used generators used plastic machinery used rubber machinery and .

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

View a 3D animated video of the cement production process to learn how cement is made by CEMEX.

Dry, semi-dry, semi-wet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the ...

Loesche has provided a LM 56 3+3 CS vertical roller mill to Attock Cement Pakistan Ltd, for the grinding of cement clinker. The new mill will be used in the new line ...

Dalmia is one of the leading cement suppliers in India; it even supplies to the top companies. The Dalmia cement factory employs the best manufacturing techniques ...

Data From: TDF Content (% TDF compared to coal) Dioxins/Furans; 4 California Cement Kilns 6,16-22: 20%: Increased between 53% and : 5 Canadian Cement .

Cement mill. Cemax full range of cement grinding aids and performance enhancer, formulated to increase cement mill throughput, reduce cement production cost and ...

WhatsApp)

WhatsApp)