WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Difference Between Dry And Wet Ball Mill Charging a wet mill the general operation of a grinding mill is to have the product impacted between the balls as they tumblenlike dry milling wet milling is more straight forward and more forgiving in terms of charging the products with dry milling there should be at least 25 liquid to fill the void space plus a bit more to insure

mining difference between dry and wet ball millDry Grinding VS Wet GrindingMineral Processing MetallurgyThe choice between wet and dry milling is in general unimportant in smallscale milling but is a major technical problem when lar

♦ Calculate the increase of soil binder from the Wet Ball Mill test as a percentage of the backcalculated original dry mass M Soil Binder Increase1 100 B−C M and M 100 B 100− A Where • A original percent soil binder determined in Step 1 of the 'Determining Disintegration of Flexible Base Material' procedure 425 µm No

Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction These ball mills are suitable for dry wet and cryogenic grinding as well as for cell disruption for DNARNA recovery Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding to analytical fineness They are used for the most demanding tasks in the laboratory from routine

Unlike dry milling wet milling is more straight forward and more forgiving in terms of charging the product As with dry milling there should be at least 25 liquid to fill the void space plus a bit more to insure the balls are striking product and not each other

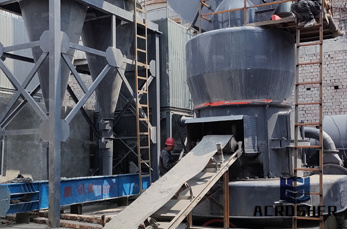

difference between dry and wet ball mill PRODCUT Crushing Equipment HJ Series Jaw Crusher PE Series Jaw Crusher PEW Series Jaw Crusher PF Series Impact Crusher PFW Series Impact Crusher Ball Mill Hammer Mill LM Vertical Grinding Mill MTM Series Trapezium Mill MTW Series Trapezium Mill XZM Series Ultrafine Mill

A slight difference of condition between the two cases however is that with dry milling the fluid air fills the whole of the mill shell not occupied by the balls whereas with wet milling the liquid occupies only a part of the mill volume not occupied by the solid charge

In this investigation we conducted batch grinding tests of monosized quartz particles with a ball mill and studied the influences of ball diameters under dry and wet grinding on the fineness and the particle size distribution of the ground product The results obtained are summarized as follows 1

Both the dry ball mill and the wet ball mill include the main parts such as the feeding part the discharging part the rotating part and the transmission part The structure of the dry ball mill is more complex than that of the wet ball mill and its discharge port is in the shape of a straight cylinder

Sep 24 2019· The differences between wet ball milling and dry ball milling are as written below Power The difference between the result gotten from using wet and dry milling are most of the time very large This difference is attributed to power The power to drive a wet ball mill is said to be 30 lesser than that of a similar dry ball mil more Loading

gradation prior to testing for soil constants and Wet Ball Mill 47 Decant all free water from sample into a 2 L 05 gal container finish filling container with clear water and use to wash sample into the mill 48 Place the six steel spheres in the mill fasten the watertight lid securely and rotate

Wet milling produces smaller particles but dry milling has the advantage that the liquid milling media does not need to be removed at the end of the process This not only saves time but also prevents the formation of hard agglomerates which can result when liquids are removed from powder suspensions

Wet and dry ball mill structure differences dry ball mill outlet is cylindricalshaped blower unit Wet ball mill outlet is trumpetshaped builtin screw device to facilitate discharge Selling most of ball mill wet ball mill on the market wet ball mill grinding high fineness dressing better

Ball Mill Wet Ball Mill Dry Ball Mill Mining The ball mill is the most important equipment in the beneficiation equipment and the structure is reasonable and price concessions Dry grinding and wet grinding are all possible and the fineness is about 800 mesh which can be adjusted Get Price Ball Milling an overview ScienceDirect Topics

Ball Mill Loading Dry Milling Ball Mill Loading dry milling When charging a ball mill ceramic lined mill pebble mill jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product

Usually wet ball milling is suitable for pretreating magnetite concentrates while dry ball milling is better for hematite concentrates because finely ground hematite concentrates are difficult to filter However dry ball milling is confronted with difficulties in dust collection and high capital investment

Oct 25 2019· The difference between the two structures is that the outlet of the dry ball mill is a straight cylinder and there is a ventilation device to exhaust dust and the outlet of the wet ball mill is a

Ogonowski et al 2018 conducted an investigation to compare wet and dry grinding processes in an electromagnetic mill They reported that for the same products dry grinding needs 3 kW of power

Charging a Wet Mill – The general operation of a grinding mill is to have the product impacted between the balls as they tumble Unlike dry milling wet milling is more straight forward and more forgiving in terms of charging the product As with dry milling there should be at least 25 liquid to fill the void space plus a bit more to insure the balls are striking product and not each other

The difference is that the structure structure of the dry ball mill is relatively more complicated than the wet ball mill and its discharge mouth is straight cylinder shape and it is equipped with air device dust pipe and dust collector which is determined by its working structure of wet ball mill is simple no need to add too many auxiliary accessories discharge mouth is like a horn builtin screw device to

WhatsApp)

WhatsApp)