WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The raw cement ingredients needed for cement production are limestone calcium sand and clay silicon aluminum iron shale fly ash mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inches

Portland cement manufacturing plants are part of hydraulic cement manufacturing which also includes natural masonry and pozzolanic cement The sixdigit Source Classification Code SCC for portland cement plants with wet process kilns is 305006 and the sixdigit SCC for plants with dry process kilns is

mill scale for making cement What are the industrial uses of mill scale apart from cement production mill scale is used in making flux for welding electrode coating mill scale is used for making iron oxide used in thermit welding by heating and converting in

For foundation footings mix one part Portland cement three parts sand and five parts gravel plus enough water to make it pour easily For outdoor paving of walks or driveways mix one part Portland cement 15 parts sand 25 parts gravel and 05 parts water Mortar is

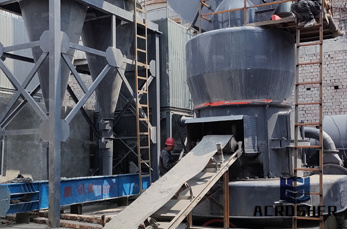

We have mill scale for making cementNov 28 2015 · Clinker is an intermediate product in the process or making a final cement product Portland cement can be manufactured using three byproducts from the iron and steel industries These three byproducts are mill scale foundry sand and slag Foundry sand can provide silica and iron which are used in the production of clinker

Cement blocks are probably the most important building material in urban Kenya They are made by mixing cement sand and small stones together and forming the mixture into blocks of varying size

A process for forming cement clinker using mill scale that may have hydrocarbons associated therewith Normal feedstock material is preheated and then transferred to a combustion area

Saucon Resources would like the opportunity to be your mill scale suppliers This material was once considered a waste stream but with the heavy depletion of standard scrap many IronSteel producers have started using mill scale to add FE units Many other industries also use mill scale such as the Cement Industry Pigments and several more

Mill scale has wide usage in the steel plant 90 of mill scale is directly recycled within steelmaking industry and a small amount is used in other industry like cement plants petrochemicals industry etc

Mill Scale Making Cement Mill Scale Making Cement Mill scale Wikipedia Mill scale often shortened to just scale is the flaky surface of hot rolled steel consisting of the mixed iron oxides ironII oxide FeO ironIII oxide Fe 2 O 3 and ironIIIII oxide Fe 3 O 4 magnetite Learn More Mill Scale Sales We are Experinced in Domestic and Export

Mill scale A byproduct of the steel production mill scale is an attractive alternative source of iron oxides for the cement industry and the chemical industry The mill scale is produced during the milling process from the sudden oxidization of the hot iron products

One of the most prominent mill scale uses is Cement Adding mill scale to the combustion area when manufacturing cement clinker converts unwanted and potentiallydangerous hydrocarbon gases into less volatile gas products

The size of the mill scale will be from dust size in microns up to normally 6 mm perhaps longer as it is scale it will flake off the steel Processes exist to recover and use the mill scale as well as all other ironFe bearing materials wastes in steel mills and use it directly in a furnace to make new steel

AlOtaibi 26 who used steel mill iron oxides as fine aggregate in cement mortars found that drying shrinkage was lower when using steel mill scale He also showed that replacing 40 of sand

Aug 30 2012· Cement Manufacturing Process Phase II Proportioning Blending Grinding The raw materials from quarry are now routed in plant laboratory where they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally limestone is 80 and remaining 20 is the clay

May 25 2018 · mill scale for making cement customer case pavagbe drum liner plates ball mill customer case Mineral 20170308 2018 Zenith Factory Price Cement Ball MillGrinding MillBall Mill Find Complete standardcement ball mill spare parts will be packed in wooden cases rotary rotary barrel inner is equipped with the appropriate ball grinding

What are the industrial uses of mill scale apart from cement production mill scale is used in making flux for welding electrode coating mill scale is used for making iron oxide used in thermit welding by heating and converting in

Mill scale is porous and poorly adherent scale of magnetite it will only give limited short term protection to steel against corrosion If you are coating any steel surface against corrosion it is necessary to blast clean with garnet or similar to a finish of Sa25 blast standard before coating

mill scale and feedstock material are thoroughly mixed and blended and the mill scale is diffused and combined with the feedstock material as the mill scale and the feedstock material move from the feed end toward the heatsource end of the rotary kiln to form cement clinker

Mill Scale For Making Cement Customer Case Environmental protection Energysaving Low cost Production capacity 12725th Max Feeding Size 2550mm Environmental Friendly Sand makers are also called sand making machines Sand maker is made primary equipment of sand production line The machine is designed for highway railway highrise construction

Mill Scale Making Cement Mill scale Wikipedia Mill scale often shortened to just scale is the flaky surface of hot rolled steel consisting of the mixed iron oxides ironII oxide FeO ironIII oxide Fe 2 O 3 and ironIIIII oxide Fe 3 O 4 magnetite

Mill Scale For Making Cement Crusher Manufacturers Quotes We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment

WhatsApp)

WhatsApp)