WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Uranium Uranium Mining & Milling. The ore is crushed and milled to separate the uranium. An intermediate product known as yellowcake (U3O8), because of its ...

Uranium processing. Uranium milling. Drum filled with yellowcake. Source: CNSC. After mining, uranium ore is transported to a nearby mill for processing.

Milling Simplified flow chart of uranium ore processing from mining to the production of concentrate. ... ore grades at operating uranium mines range from

Uranium ore is simply rock with elevated amounts of uranium in it. Once the rock has been removed by open pit or underground mining it must be milled to separate the ...

URANIUM MINES Most uranium ore is mined in open pit or underground mines. The uranium content of the ore is often between only 0.1% and 0.2%. Therefore, large .

URANIUM MINING, MILLING AND TAILINGS DISPOSAL – BEST PRACTICES by R. GUPTA, ... Mining of uranium ore b) Milling of the ore to extract uranium c) ...

10.08.2017· Uranium Mining Overview ... In Australia all uranium mining and milling ... McArthur River has enormous high-grade reserves of over 20% uranium ore ...

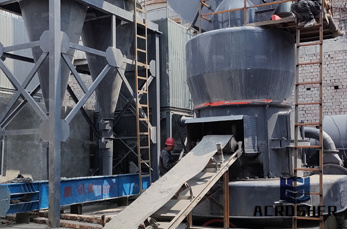

uranium ore milling process - Coal Surface Mining. uranium ore milling process Description : NRC: Conventional Uranium Mills A conventional uranium mill is a .

Yellowcake,Wikipedia, the free encyclopedia. Yellowcake (also called urania) is a type of uranium concentrate powder obtained from leach solutions, in an intermediate ...

SAFETY SERIES No. 44 Management of Wastes from the Mining and Milling of Uranium and Thorium Ores A Code of Practice and Guide to the Code This publication .

08.05.2017· Milling of Uranium Ores on ResearchGate, the professional network for scientists.

12.08.2017· At the mill, uranium ore undergoes a variety of changes to turn it into a finished product: uranium powder, also known as yellowcake. The milling process ...

Environmental impacts of uranium mining and milling - Slide Talk ... Consequences of uranium ore wet metallurgy processing in MAPE - Mydlovary area at Vodňany, ...

URANIUM ORE: MINING AND MILLING NUCLEAR FUEL CYCLE – SH2609 Primary sources of information: (1) Uranium Extraction Technology, IAEA 1993 (2) The Nuclear .

Conventional Uranium Mills. Conventional milling is one of the two primary recovery methods that are currently used to extract uranium from mined ore.

----- ABSTRACT The report presents an overview of the uranium mining, milling, and refining industry of the United States. Topics discussed include ore reserves ...

Grinding Of Uranium Ore ... Uranium Processing Plant Uranium mine crusher, uranium milling, uranium beneficiation, uranium processing plant » Learn More.

coal ball mill design calculations - YouTube. 23 Jun 2013 ... Ball mill Ore Crusher Uranium ore ... ball mill sizing calculationcoal hammer mill sizing calculation ...

yellow is the result of milling uranium ore Welcome to Shanghai CNcrusher Mining and Construction Machinery Co., Ltd.

Mining, Milling, Conversion and Enrichment of Uranium Ores ... ore processing (milling) to provide uranium oxide concentrate ... Uranium Ore Types

1 NATIONAL COMMISSION FOR NUCLEAR ACTIVITIES CONTROL URANIUM MINING AND MILLING IN ROMANIA Nicolae Dumitrescu National Commission for Nuclear Activities Control - Romania

Uranium; How is it Mined? What Is Uranium? ... The milling process involves crushing and pulverizing the rock into ... While not all uranium ore deposits are ...

Uranium mining is the process of extraction of uranium ore from the ground. The worldwide production of uranium in 2015 amounted to 60,496 tonnes.

To produce this amount of uranium, about 440,000 tons of uranium ore have to be processed. International ... 2.1.2. Uranium mills Milling process.

WhatsApp)

WhatsApp)